What does a logistics control system have to do with calorific value optimization? More than you think, at least with waste incineration plants. Here is a brief history of BERTHOLD’s ongoing projects at Wien Energie:

Wien Energie operates all 4 waste incineration plants in Vienna. A profound team of experts is constantly working on optimizations to make thermal waste recycling safe, efficient and environmentally friendly.

BERTHOLD supports the restless professionals as a long-term partner for the development and implementation of efficient logistics solutions.

The hunt for the optimal combustion process

Naturally, a central focus is on the combustion process itself:

The aim is the best possible, continuous calorific value despite the different calorific values of the delivered waste.

The following applies: the lowest possible environmental impact with the best thermal yield at the same time.

One of the particular challenges lies in the fact that waste is seldom delivered on a demand-driven basis, but rather on a production-driven basis. This is exactly where the latest expansion of the logistics concept comes in:

New traffic concept supports heating value optimization in MVA Spittelau

The BLS logistics control system has now been expanded by BERTHOLD to include innovative features relating to the integrated traffic control system – after an intensive, joint development process.

The employees of Wien Energie receive innovative tools to be able to achieve a better homogenization of the waste with different calorific values already upon delivery.

The new features are based on the already integrated scheduling:

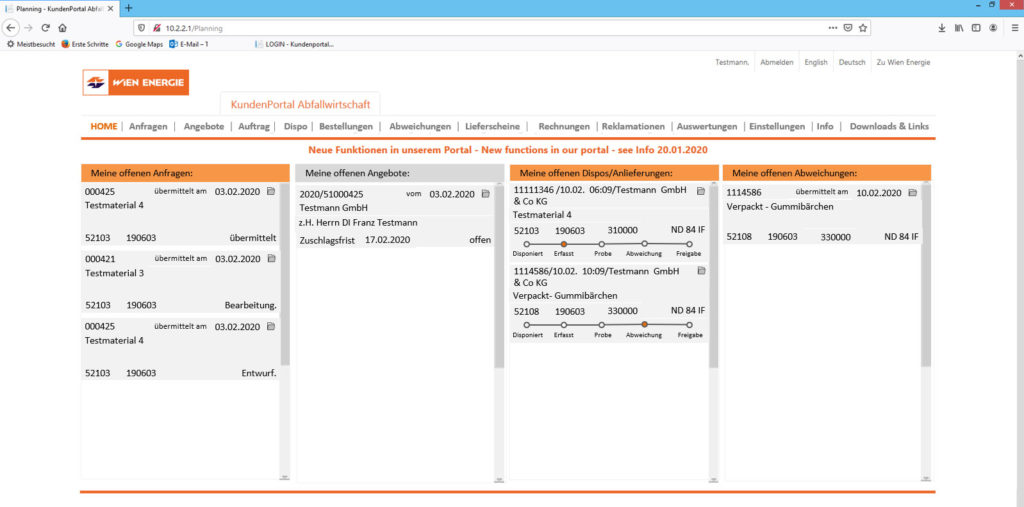

Planned deliveries by municipal and private delivery companies are recorded digitally, e.g. using a customer portal. All relevant data, as well as the classification of the calorific value, are therefore available in BLS in advance.

On delivery, trucks can soon be ranked according to the classification of the calorific value in high and low calorific value:

Demand-driven routines

“Fast lane”

Traffic guidance system

Additional waiting area for trucks

Re-check at the bunker gate

The crane receives data from the BLS logistics control system

Together, these features create the possibility of influencing the waste deliveries in a targeted manner for an optimized calorific value.

In the course of these extensions, the BERTHOLD technicians also renewed the control of the hydraulic flaps and brought them up to date.

The implementation of this project will take place at the end of September – beginning of October 2021.

In addition to this exciting project, BERTHOLD is working on 2 further optimizations for Wien Energie:

Further expansion of the customer portal

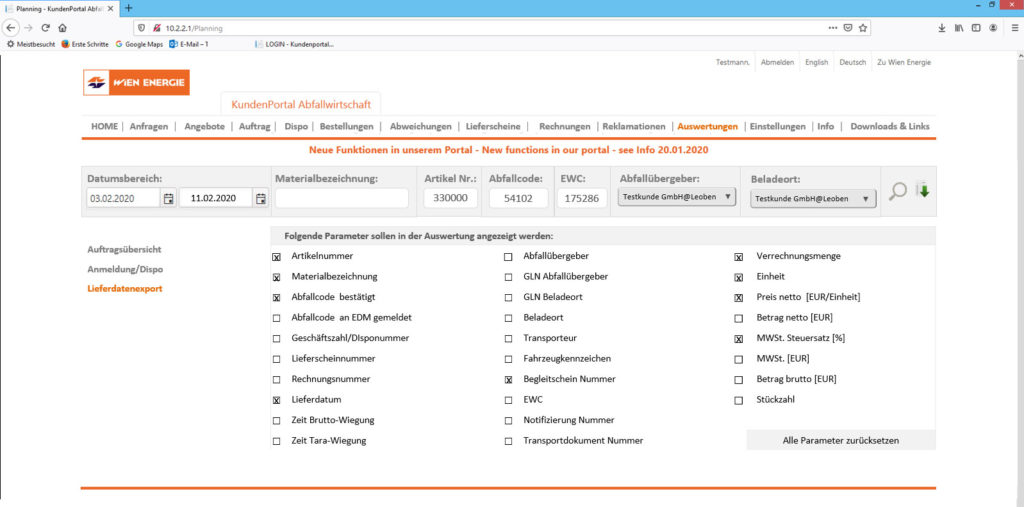

As reported, Wien Energie uses the BLS customer portal from BERTHOLD: Based on the BLS logistics control system, the BLS customer portal enables all customers and suppliers approved for this to have web-based, direct access to the relevant part of the BLS data landscape. Wien Energie has proven the added value of these extensive tools in practice.

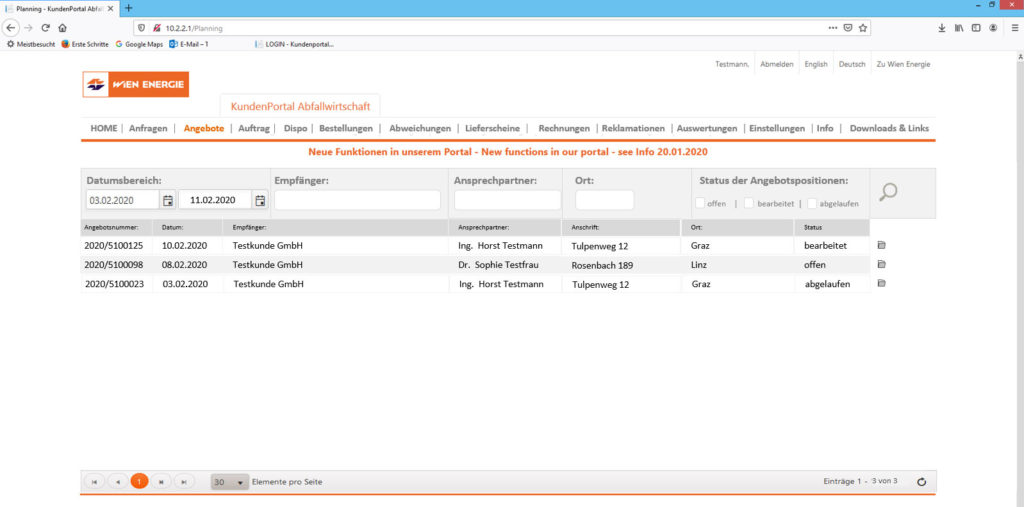

On behalf of Wien Energie, BERTHOLD developed further practical modules so that the entire inquiry and offer system merges into one integrated system.

These extensions will be available to customers of the Simmering waste incineration plant in September 2021.

Ongoing software updates: Always up-to-date with the latest technical information with a maintenance contract

The core software from BLS, including its modules, is also constantly being further developed. New functions are added (e.g. a new log system), practical features and new designs increase ease of use. The latest technical status generally ensures a high level of operational reliability for the system.

All BLS users with a full maintenance contract receive these updates at no additional cost. The implementation takes place in consultation with the customer via remote maintenance or on site.

Wien Energie relies on this future-proof concept: The software of the BLS logistics control system was recently upgraded to the latest technical standard at all 4 locations.

The BLS logistics control system: the right platform for constant innovation

Due to the open and modular structure and the great experience of the BERTHOLD technicians, the BLS logistics control system offers a wide range of options for process optimization.

BLS expansions are investments that quickly pay off: well prepared and implemented in a targeted manner, they increase profitability and security.

We look forward to accompanying Wien Energie through numerous optimization processes over the years, thank you for the close and always constructive cooperation and look forward to future joint projects!