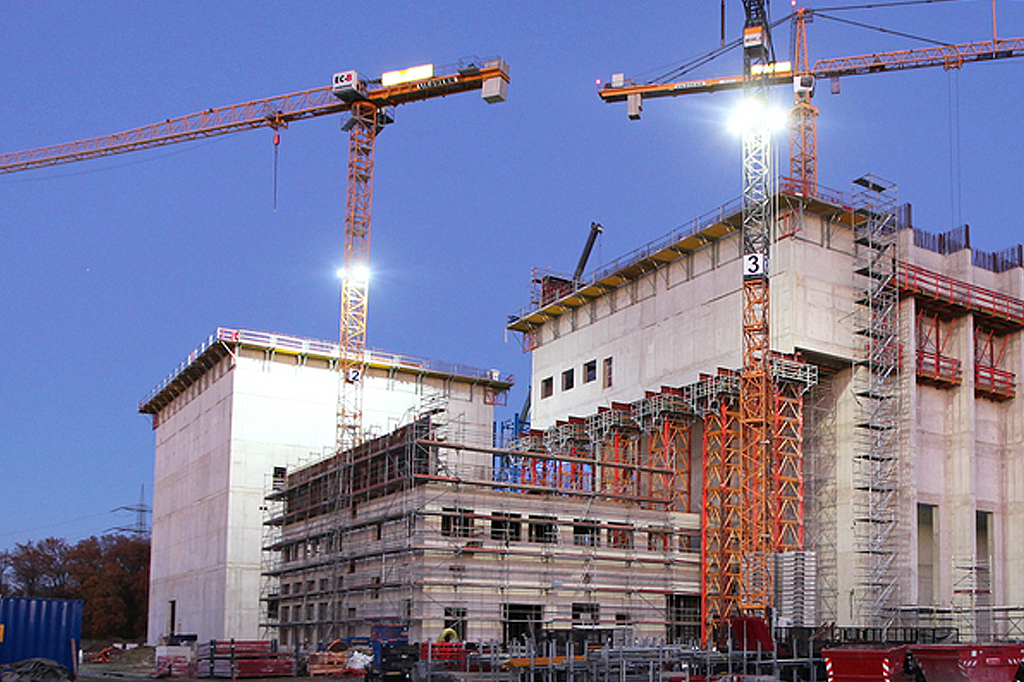

The construction work is still in full swing, but from 2023 the wood energy center in Dinslaken/NRW will supply almost climate-neutral energy. BERTHOLD’s tried-and-tested BLS logistics control system will ensure safe and economical handling of the transport logistics.

BERTHOLD has earned an excellent reputation among operators and planners of thermal power plants. State-of-the-art and field-tested technology, extensive industry knowledge, high flexibility and a team of technicians who work efficiently and in a solution-oriented manner.

Users such as Wien Energie, EVN, Interargem, Renergia and iwb appreciate the practical relevance and high operational reliability of the BLS logistics control system, which BERTHOLD developed in-house and is therefore the market leader.

Municipal Services Dinslaken is preparing for the future

Like many other energy suppliers in Europe, the Municipial Services Dinslaken are also preparing to the coal phase-out. With the Dinslakener Holz-Energiezentrum (DHE) an almost CO2-neutral alternative is being built: A power and heat generation plant with which the city’s heat requirements can be covered self-sufficiently and sustainably in the long term.

The state-of-the-art wood-fired thermal power station will thermally utilize an average of 187,000t of waste wood per year and supply 380 GWh of heat and around 100 GWh of electricity. The wood is delivered directly from the region by truck.

The operators rely on the tried-and-tested BLS logistics control system from BERTHOLD for automated processing of the deliveries of raw materials, operating materials and auxiliary materials.

Among other things, the consistently positive experiences of existing BLS users, which were confirmed during reference visits to Renergia and iwb, were decisive for this decision.

Total project scope

The BLS logistics control system is individually designed to meet the requirements and processes of the Dinslaken wood energy center. BERTHOLD supplies BLS as a complete turnkey system, including all the necessary peripheral devices.

The BLS software completely covers the entire logistics process, from access control and factory security, disposition to processing and transfer to a financial accounting system for invoicing.

Services

- Engineering

- Assembling & connection

- Installation

- Startup

- Trailrun

- Training

Software

- BLS software including configuration

- Interfaces to the bunker gates, crane and the process control technology

Hardware

- 1 BLS terminal compact and 1 ID box at the entrance area

- 1 ID column at the exit area

- 2 self-service terminals incl. scale evaluation on separately located scales

- 1 radioactivity measuring point (transmitter/receiver)

- 14 additional ID boxes at relevant positions of the logistics process

- 1 call display in truck waiting area gates 1-6

- Traffic control technology Traffic lights, cameras, barriers

- Control of the bunker gates

Thanks to extensive features, BLS can automatically handle the entire transport logistics process chain in ONE system.

Traffic control system for smooth operation

BERTHOLD is also responsible for the delivery of a traffic control system for smooth operation and the best possible use of the existing traffic areas.

Together with the customer and the planning office, a traffic concept is developed as part of the implementation planning, which takes all special features into account: The internal traffic can thus be controlled safely and fully automatically.

All required components are part of the scope of delivery from BERTHOLD:

• PLC for the traffic management system

• Traffic lights at scales and gates

• Barriers at the entrance and exit of the weighbridge and at the 3 entry/exit lanes

• Cameras

• Induction loops

• Interface to the crane and to the control system

BERTHOLD looks forward to professional cooperation

Work on the precise detailed planning of this important project is already underway together with the project team from Stadtwerke Dinslaken and the planning office SEEGER Engineering GmbH. Finally, the complete logistics control system for a factory acceptance test is to be set up in autumn/winter 2022, so that assembly can take place on site at the beginning of 2023.

The BERTHOLD team is looking forward to continued good cooperation!

Stadtwerke Dinslaken/North Rhine-Westphalia

With 24 subsidiaries and associated companies, the Stadtwerke Dinslaken Group is one of the largest regional energy specialists in Germany.

DHE – Dinslaken Wood Energy Center

On the basis of waste wood, around 380 GWh of heat will be generated in the ultra-modern plant in future in an almost climate-neutral manner. At the same time, electricity is produced in the DHE using combined heat and power generation. This makes the system particularly climate-friendly and efficient.

The output generated by the DHE corresponds to approx. 100% of Dinslaken’s current heat and electricity requirements, which means that 17,000 single-family homes can be supplied.

With the commissioning of the Dinslaken wood energy center, an additional 125,000 t of CO2 can be saved in the future.

Images from external source:

Photo credits: Stadtwerke Dinslaken GmbH