Joint successes should be celebrated together: The Swiss wood power plant Aarberg AG invited to the opening ceremony of the newly built wood power plant. Also there: the high-tech company BERTHOLD from Austria.

The Aarberg wood-fired power plant has been running successfully in full operation since January 2021. Thanks to the extremely good cooperation between all the companies involved, this innovation project was completed on schedule despite the tight deadline.

We also had to celebrate this great success together. At the invitation of Holzkraftwerk Aarberg AG, numerous employees from all project partners came to the opening ceremony on September 17, 2021, which was relocated before the beginning of autumn due to the pandemic.

BERTHOLD, represented by project manager Christian Hauser and responsible for the planning and implementation of the innovative logistics control system as well as the internal traffic control system (see project report) gladly accepted this invitation.

In speeches by Andreas Blank / Schweizer Zucker AG, Government Councilor Christoph Neuhaus, President of the National Council Andreas Aebi, Dr. Beat Brechbühl / AVAG and Daniel Allemann / Terra Nova GmbH emphasized the importance and innovative strength of this successful project as well as the positive effects on the region and climate.

The sociable part followed with a typical Swiss Apéro Riche, also with the possibility of an individual tour of the wood power plant. In late summer weather, the party ended in a cozy atmosphere.

Celebrating common successes together – that is what distinguishes successful partnerships.

The BERTHOLD team is pleased to be part of this partnership and to have made an important contribution to its success.

The project

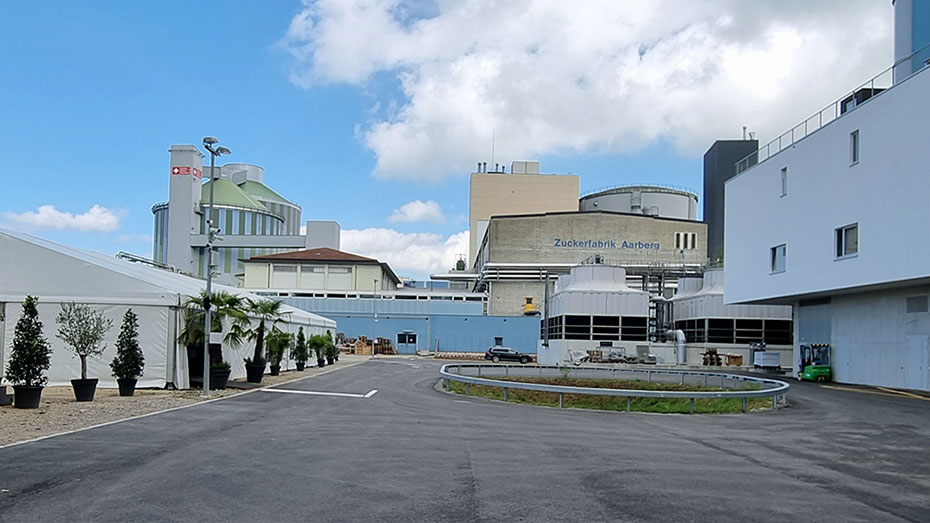

Schweizer Zucker AG, AG für Abfallverwertung (AVAG) and Terra Nova GmbH set up a groundbreaking environmental project on the site of the sugar factory in Aarberg: an innovative wood-fired thermal power station supplies the sugar factory with steam and district heating.

Thanks to this CHF 95 million investment, Schweizer Zucker AG can reduce its fossil fuel consumption by around 60% at its Aarberg plant.

The generated renewable electricity of around 70,000 MWh per year is fed into BKW’s public grid. This roughly corresponds to the total annual consumption of 9,750 people for living, leisure and work.

While Terra Nova is responsible for the procurement of waste wood, while AVAG is also responsible for the operation of the power plant, the Schweizer Zucker AG is the buyer of the heat from the wood-fired power plant.

The Swiss Sugar AG

Schweizer Zucker AG (SZU) is the only company in Switzerland that processes sugar beet and supplies the Swiss market with sugar and the resulting feed. This gives SZU a market-leading position in terms of quantity, quality and readiness for delivery.

Terra Nova GmbH

As a Swiss company, Terra Nova GmbH offers “from the garbage can to the socket”

forward-looking disposal solutions. It is part of the B+T Group, a leading European address for waste recycling. With innovative ideas, residues are put to a meaningful use in efficient and sustainable material and energy cycles.

AG for waste recycling AVAG

AVAG is the leading regional provider of total disposal, recycling and energy solutions in the Aaare, Gürbe and Emmental valleys as well as in the Bernese Oberland. For around 134 municipalities and their resident companies, it has ensured environmentally friendly, responsible and economical disposal since 1973.